We work obsessively to ensure that the trust reposed in brand “SOTRA TMT” is never compromised.

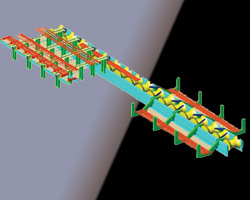

The Melting Shop used by Sotrafer for the production of standard mild steel grade is equipped with a 12-ton UHP Furnace (Electrotherm) and an AOD converter with a 15-ton capacity. The Casting process carries out through a continuous casting machine in square billet 100 MM². The Billet is ground and inspected to eliminate all the surface defects due to casting operations. Online, the hot rolling process is performed in a fully automatic bar mill under SABS Standards consisting Re-heating furnace, roughing mill stands, intermediate mill stands, and a continuous mill, capable of producing bars from 6 mm to 32 mm. Thermo-mechanical treatment (TMT) process gives the final surface aspect and mechanical characteristics to TMT Bar which ultimately, as a Produce introduced to the market as (SOTRA TMT).

Over the course of more than 25 years of hard work with many large and small projects. We have worked out the best working process.

The raw material is duly tested in modern computerized labs before sending for rolling. After heating up to optimum temperature of 1000° to 1100° C, the raw material starts taking shape as per rolling pass schedule and reduction through mill stands.

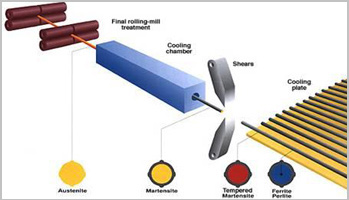

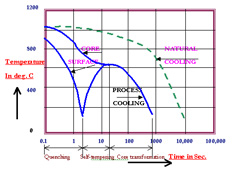

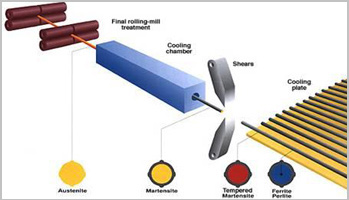

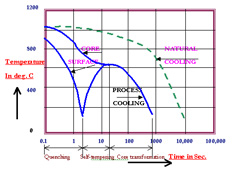

The bar leaving the final mill stand at about 900°C pass through specially designed quenching box. The red hot bars are subject to sudden and intense cooling. The cooling time and rate depends on the size of the bars controlled by maintaining a desired temperature; follow rate and temperature of water. The surface get quenched allowing the outer layer of the bar to a reduced temperature of 300°C and forms a hard marten site structure while inner layer remains comparatively hot & austenite.

Now the heat follows from the core to the outer surface making the hard marten site layer into solid structure as the core still remains austenite at this stage.

The bar is kept on cooling bed getting cooled by natural air transforming the core into ductile – ferrite – pearlite solid structure. Further cooling changes the rest of the austenite change into fine grained ferrite and partite structure, giving a balance combination of high strength, ductility and toughness making the rebar earthquake resistant.

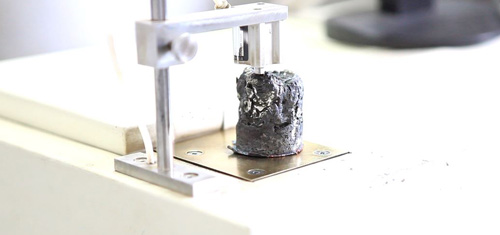

Sotrafer ensures quality at every step, from the input of raw material to the final product delivered on site. With a high automated plant and continuous checks at various levels, Sotrafer is able to produce higher quality TMT bars in the country. The quality team is equipped with modern testing facilities which ensure that the products meet stringent SABS norms and quality standards. Spectrometer, UTM testing machine with Extensometer, Bend and Re-bend equipment and software for plotting and printing the stress train test graph.

We work obsessively to ensure that the trust reposed in brand “SOTRA TMT” is never compromised.

The raw material is duly tested in modern computerized labs before sending for rolling. After heating up to optimum temperature of 1000° to 1100° C, the raw material starts taking shape as per rolling pass schedule and reduction through mill stands.

Now the heat follows from the core to the outer surface making the hard marten site layer into solid structure as the core still remains austenite at this stage.

The bar is kept on cooling bed getting cooled by natural air transforming the core into ductile – ferrite – pearlite solid structure. Further cooling changes the rest of the austenite change into fine grained ferrite and partite structure, giving a balance combination of high strength, ductility and toughness making the rebar earthquake resistant.

Sotrafer ensures quality at every step, from the input of raw material to the final product delivered on site. With a high automated plant and continuous checks at various levels, Sotrafer is able to produce higher quality TMT bars in the country. The quality team is equipped with modern testing facilities which ensure that the products meet stringent SABS norms and quality standards. Spectrometer, UTM testing machine with Extensometer, Bend and Re-bend equipment and software for plotting and printing the stress train test graph.

We work obsessively to ensure that the trust reposed in brand “SOTRA TMT” is never compromised.

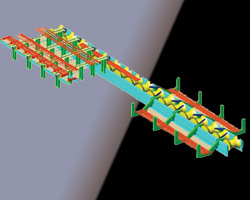

The salient features of the rolling mill include an extensive Billet / ingot yard for stacking of Billet / ingot, reheating furnace, Roughing mill, Intermediate mill & finishing mill, continuous shear to cut finished TMT bars, besides the most modern TMT facilities.

This technology is introduced by “SSS” Technologies. A contemporary technology, it allows the production of bars to be on par with SABS standards. Hot rolled from steel Billet / ingot and subjected to PLC-controlled online thermo-mechanical treatment, the bars are made to pass through heat treatment over four successive stages.